Top reasons to choose used bulk containers for practical business operations

The Ultimate Overview to Picking the Right Mass Containers for Your Business Demands

Choosing the proper mass containers is crucial for any kind of service that relies upon effective logistics. Various kinds of containers exist, each designed for details materials and applications. Elements such as size, product compatibility, and governing standards play a substantial duty in this decision-making process. Understanding these aspects can lead to boosted functional efficiency. Lots of businesses overlook necessary aspects that might boost their overall efficiency and sustainability. What are these considerations?

Comprehending Various Kinds of Mass Containers

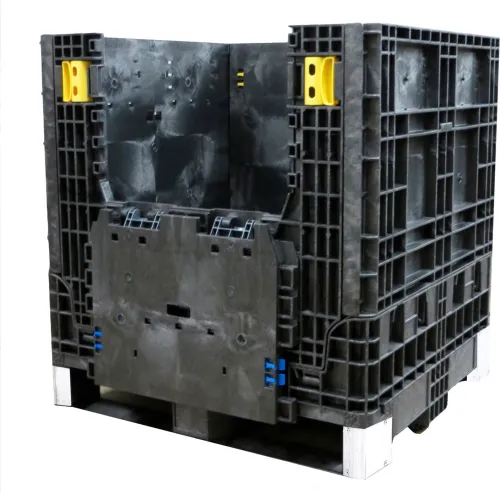

Mass containers work as necessary devices for services looking for efficient storage space and transport remedies. These containers come in various types, each developed to satisfy details functional demands. One typical type is the intermediate bulk container (IBC), which is perfect for granulated and liquid products, offering a balance of capability and maneuverability. Another popular alternative is the mass bag, or FIBC, ideal for dry, flowable items. These flexible containers are lightweight and can be easily transferred and saved. For heavier products, inflexible bulk containers are often used, providing resilience and stability for secure handling. In addition, there are customized containers tailored for hazardous products, ensuring compliance with safety and security regulations. Comprehending the distinctive qualities of these mass container types enables businesses to make informed choices that maximize logistics and minimize costs. By picking the ideal container, business can enhance their operational performance and enhance their supply chain procedures.

Secret Material Factors To Consider for Bulk Containers

When selecting mass containers, it is important to consider the materials made use of in their building. Variables such as sturdiness, strength, and chemical compatibility play an essential role in making certain the containers fulfill certain operational demands. In addition, weight and portability problems can affect both efficiency and transport logistics.

Product Sturdiness and Toughness

Longevity and toughness are vital factors in picking products for mass containers, as they straight influence the container's capacity to stand up to various environmental conditions and taking care of processes. Products such as high-density polyethylene (HDPE), polypropylene, and stainless-steel are generally favored for their durable residential properties, supplying resistance to temperature level, impact, and abrasion changes. The choice of product additionally affects the total life-span of the container; stronger materials commonly cause less regular replacements, causing set you back financial savings gradually. In addition, the weight of the product can affect delivery expenses and convenience of handling. Organizations must consider their particular functional atmospheres and the capacity for deterioration to guarantee peak resilience and toughness in their mass container selection.

Chemical Compatibility Factors

Comprehending chemical compatibility is important for selecting bulk containers, as the materials made use of should stand up to the particular substances they will hold. Numerous variables influence compatibility, consisting of the chemical nature of the components, temperature, and period of storage space. For instance, corrosive chemicals might call for containers made from stainless steel or specialized plastics that withstand deterioration. Furthermore, reactive materials can produce heat or gases, demanding vented or pressure-rated containers. The selection of container material, whether polycarbonate, steel, or polyethylene, ought to align with the chemical residential or commercial properties of the saved compounds to avoid violations or leaks. Ultimately, a thorough analysis of these compatibility aspects assures secure handling and storage, protecting both workers and the setting while preserving product honesty.

Weight and Mobility Concerns

Choosing mass containers involves not only assessing chemical compatibility however additionally considering weight and mobility. Companies need to evaluate the simplicity of handling and transport to enhance efficiency. Lightweight products like high-density polyethylene (HDPE) or light weight aluminum can assist in less complicated motion and reduce delivery costs. On the other hand, larger containers might provide enhanced durability but can prevent movement, especially in settings requiring frequent relocation. In addition, the style of the container should enable convenient training and piling, ensuring ergonomic safety for employees. Firms need to additionally consider the facilities offered for transport; as an example, containers suitable with forklifts or pallet jacks can simplify procedures. Ultimately, the right balance in between weight and portability directly influences operational effectiveness and cost efficiency.

Sizing Your Bulk Containers for Ideal Efficiency

When sizing mass containers, companies have to carefully assess the dimensions needed to suit their details items. Additionally, weight capability is a critical element that influences effectiveness and safety and security throughout transport and storage space. Effective sizing not just makes best use of space however also maximizes operational workflows.

Determining Container Capacities

Choosing the appropriate dimensions for mass containers is important for maximizing effectiveness in storage and transportation. Organizations need to assess their particular requirements, considering variables such as offered room, the nature of the products being stored, and the approaches of transport used. Accurate measurements ensure that containers fit preferably in lorries and stockrooms, decreasing lost area and reducing handling time. Criterion dimensions can use benefit, yet personalized dimensions might be needed for special requirements or to fit details products. Additionally, it is necessary to review piling abilities and availability, as these factors influence total functional performance. Ultimately, the right dimensions cause improved organization and structured logistics, benefiting the total efficiency of the organization.

Weight Ability Considerations

Comprehending weight capability is important for services intending to enhance their mass container effectiveness. The weight ability of a container directly affects storage abilities, transport logistics, and general functional expenses. Choosing containers with the appropriate weight limitations ensures that businesses can safely store and move their items without taking the chance of damages or compliance concerns. Straining containers can result in structural failures, while underutilizing capacity lead to thrown away resources. It is vital for companies to analyze their item weights and think about any type of regulatory demands when choosing containers. Additionally, factors such as the sort of material, intended usage, and environmental conditions need to likewise influence weight ability choices. By evaluating these components, organizations can enhance efficiency and assure a structured supply chain.

Regulative Conformity and Safety And Security Specifications

Regulatory compliance and security standards play a vital duty in the selection of mass containers for companies. Organizations must guarantee that their containers satisfy various regulations set by neighborhood, nationwide, and worldwide authorities. These standards commonly refer to product safety, structural honesty, and appropriate labeling, which help prevent accidents and ensure the safe transportation of products.

In addition, adherence to industry-specific guidelines, such as those from the Food and Medicine Management (FDA) or the Occupational Safety and Health And Wellness Management (OSHA), is critical for firms taking care of unsafe products or foodstuff. Non-compliance can lead to fines, legal issues, or damage to a business's online reputation.

Businesses should likewise think about the container's compatibility with the materials being stored or moved to avoid contamination or chemical reactions (used collapsible containers). To summarize, recognizing and executing regulative conformity and safety and security requirements is vital for the liable and efficient use of mass containers

Sustainability Options for Eco-Friendly Bulk Containers

Business are additionally discovering choices made from recycled products, which not only preserve resources however likewise sustain the recycling market. Innovations in layout enable for lighter containers that need much less energy to transportation, additionally boosting sustainability. By incorporating these eco-friendly mass container choices, services can show their commitment to ecological stewardship while meeting customer demand for lasting methods. This shift not only aids the earth yet can also improve brand name credibility and client commitment.

Cost-Effectiveness and Budgeting for Mass Containers

While several services concentrate on sustainability, cost-effectiveness remains a crucial variable when picking mass containers. Organizations should examine the first purchase cost, in addition to lasting functional expenses, to assure monetary viability. Elements such as upkeep, durability, and reusability play a considerable duty in establishing overall expenses.

Spending in high-grade containers might generate higher upfront prices but can result in cost savings via lowered substitute prices and lowered waste. Additionally, organizations must think about transport prices and storage efficiency, as these can impact the general budget.

Often Asked Inquiries

Just how Do I Establish the Right Container for Hazardous Materials?

To figure out the best container for hazardous materials, one need to review compatibility with the compound, take into consideration the container's product, check for regulative compliance, and assess capability and safety attributes to assure correct handling and storage space.

Can Bulk Containers Be Personalized for Particular Products?

Yes, bulk containers can be tailored for particular items. used collapsible bulk containers. Different attributes, such as size, product, and layout, can be customized to fulfill one-of-a-kind requirements, guaranteeing optimal security and performance for moving and saving different items

What Is the Average Life-span of Different Bulk Container Kind?

The average life expectancy of mass container kinds differs; plastic containers last 5-10 years, metal containers 10-20 years, and wooden containers usually last 3-7 years, relying on usage, maintenance, and environmental problems.

How Should I Clean and Maintain Mass Containers?

To cleanse and keep bulk containers, one should consistently examine for damage, get rid of residue, laundry with proper cleaning agents, wash extensively, and guarantee proper drying out before storage. Adhering to supplier standards improves long life and security throughout usage.

Exist Rental Alternatives for Bulk Containers Available?

Yes, various companies provide rental options for bulk containers, offering flexibility for companies. These leasings can suit numerous needs, allowing companies to read more handle inventory successfully without the commitment of acquiring containers outright.

Longevity and stamina are critical aspects in selecting products for mass containers, as they straight affect the container's capability to withstand different environmental problems and managing procedures. Recognizing chemical compatibility is necessary for selecting bulk containers, as the products utilized must resist the certain compounds they will hold. Recognizing weight capacity is vital for businesses intending to maximize their mass container effectiveness. Governing conformity and security criteria play a necessary function in the choice of mass containers for services. While lots of organizations concentrate on sustainability, cost-effectiveness continues to be a critical element when choosing mass containers.